Warehouse operations are no longer just about the storage and retrieval of products. They are the central hub of a company’s supply chain and play a critical role in determining efficiency, productivity, and overall operational costs. One of the most significant factors affecting these elements is warehouse design. Optimizing your warehouse layout can significantly reduce labor costs, boost productivity, and enhance overall operational efficiency. This article delves into how smart warehouse design can help reduce labor costs and how solutions like Shipedge can facilitate this transformation.

The Impact of Warehouse Design on Labor Costs

Labor represents one of the largest operational costs within a warehouse. From receiving to put-away, picking, packing, and shipping, each process involves labor. Therefore, any improvement in efficiency can lead to substantial cost savings. An effective warehouse design directly impacts labor efficiency by reducing unnecessary movements, streamlining processes, and improving ergonomics.

Discover how our WMS can improve your business

Strategies for Warehouse Design to Reduce Labor Costs

Here are some strategies for warehouse design aimed at minimizing labor costs:

- 1. Optimal Space Utilization: Efficient use of available space reduces travel times, increasing productivity. It involves smart placement of aisles, racks, and workstations, along with considering vertical space.

- 2. Workflow Design: Design workflows to minimize movement. Analyze your order profiles to create logical picking paths and cluster commonly picked items together.

- 3. Ergonomics: Consider worker safety and comfort in the design. Ergonomic workstations reduce fatigue and the risk of injury, increasing productivity.

- 4. Automation: Implement automation where possible to reduce manual tasks. This could include conveyor systems, automated storage and retrieval systems (AS/RS), and robotic process automation (RPA).

- 5. Cross-Docking: For fast-moving items, consider a cross-docking strategy where incoming goods are directly transferred to outbound gates, minimizing storage and handling.

- 6. Technology Adoption: Use technology to assist in design and daily operations. Warehouse management systems (WMS) can optimize picking routes, while technologies like RFID and barcodes can speed up processes.

The Role of Warehouse Layout in Picking Efficiency

Picking represents one of the most labor-intensive operations in a warehouse. It’s also an area where costs can quickly escalate if not managed properly. A poorly designed warehouse layout can result in inefficient picking routes, resulting in pickers walking longer distances and wasting valuable time. By incorporating efficient warehouse design strategies, such as zoning and wave picking, labor costs can be significantly reduced.

Zoning and Wave Picking

Zoning involves assigning pickers to specific areas in the warehouse, reducing unnecessary movement across the warehouse floor. Wave picking, on the other hand, involves grouping orders into “waves” to be picked at specific times. Both strategies, when implemented correctly, can optimize picking efficiency and reduce labor costs.

READ MORE: 7 Effective Picking Methods for Maximizing Warehouse Efficiency

The Power of Slotting

Another crucial aspect of warehouse design is slotting – the process of determining the best place to store an item in a warehouse. Effective slotting can streamline picking processes, reduce travel time, and enhance overall productivity. A dynamic slotting strategy, supported by a robust warehouse management system like Shipedge, can adapt to changing inventory levels and demand patterns, providing a further edge in labor cost reduction.

Training and Skill Development

Warehouse design is not only about physical layout and process optimization but also about people. Providing ongoing training to your workforce on efficient practices, new technologies, and safety measures can boost their productivity. Well-trained employees are more efficient, make fewer mistakes, and contribute to reducing labor costs.

Discover how our WMS can improve your business

Flexibility in Warehouse Design

A final factor to consider in warehouse design is flexibility. The eCommerce landscape is dynamic, with customer demand patterns changing rapidly. Designing your warehouse for flexibility can help you quickly adapt to these changes without incurring significant costs. This could include modular storage systems or adjustable workstations.

Streamlining Warehouse Design with Shipedge

Implementing these strategies is made simpler with the help of a robust Warehouse Management System like Shipedge. After years of warehouse science research, Shipedge has determined the best way to organize your warehouse to best communicate with your WMS for both efficiency and productivity. The short video below explains warehouse design best practices:

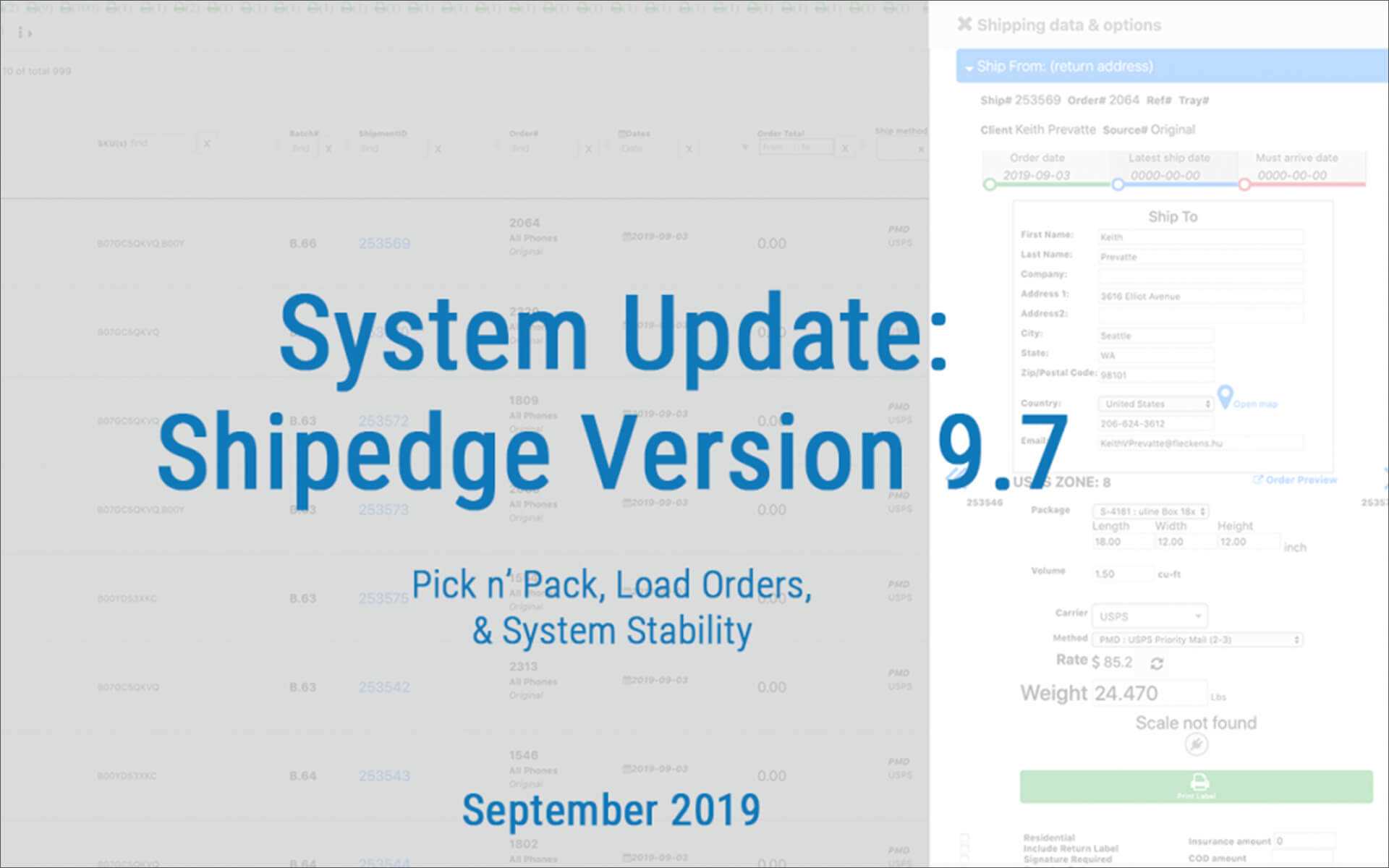

Shipedge’s sophisticated software offers features to optimize warehouse design and operations:

- Inventory Management: Shipedge offers real-time visibility of inventory across the warehouse, ensuring efficient storage and retrieval.

- Automated Picking Routes: The software can generate optimized picking routes, reducing travel time and boosting productivity.

- Integration with Automation Systems: Shipedge seamlessly integrates with various automation systems, facilitating efficient and cost-effective operations.

- Performance Analytics: With detailed analytics, you can monitor warehouse operations and identify areas for improvement.

Conclusion

An effective warehouse design plays a crucial role in reducing labor costs, directly impacting your bottom line. While designing or redesigning a warehouse can seem daunting, the right approach, coupled with advanced solutions like Shipedge, can make the process seamless and rewarding. As eCommerce continues to grow, optimizing warehouse design becomes not just a competitive advantage, but a business necessity.

Discover how our WMS can improve your business

0 Comments