Efficient inventory management plays a pivotal role in ensuring business success. One integral aspect of this management is inventory turnover, a measure of how frequently an enterprise sells and replaces its inventory within a specific period. While there are numerous strategies to enhance inventory turnover, employing lot control—a process that tracks products based on their production batches—provides businesses with increased visibility, enhanced traceability, and better control over their inventory. This article delves into the intricacies of lot control, detailing its benefits, how it aids inventory turnover, and how solutions like Shipedge can offer an edge in its effective implementation.

The Essentials of Lot Control

Defining Lot Control

Lot control refers to the practice of tracking products based on their production runs or batches, primarily using a unique identifier known as the lot number. Essentially, it enables businesses to monitor and control a specific batch of inventory, providing vital data about the products, such as their manufacturing date, location, and more. It forms the backbone of supply chain traceability, allowing a seamless follow-through from production to distribution.

The Role of Lot Numbers in eCommerce

In the realm of eCommerce, lot numbers bear immense significance. When customers or (hopefully) your quality control (QC) team identify product defects, lot numbers become instrumental in tracing the product back to its specific production lot.

This traceability allows you to swiftly get in touch with your supplier for refunds if needed. Moreover, lot numbers provide an added layer of security in eCommerce, allowing businesses to manage potential recalls more efficiently.

The Significance of Lot Numbers in Inventory Management

Inventory management benefits immensely from the use of lot numbers. Manufacturers assign lot numbers to specific batches or runs of products, offering a crucial traceability tool in managing relationships with suppliers. For instance, in the event of a product defect, a system like Shipedge, which incorporates lot control, allows the defective product to be traced back to a particular production batch. This traceability is key to interacting with manufacturers to correct production issues or request refunds.

READ MORE: Mastering Lot Control and Lot Numbers in Warehouse Management

Benefits of Lot Control

Compliance Assurance

In many industries, businesses must comply with strict rules or regulations. Lot control is a robust tool to ensure this compliance. It creates a systematic record of the product’s journey, demonstrating transparency, accountability, and adherence to industry standards. This information, when recorded and reported properly through a system like Shipedge, can be critical in maintaining regulatory compliance.

Customer Protection Through Recall Procedures

Another paramount benefit of lot control is the ability to protect customers in the event of a product recall. Lot numbers make it possible to swiftly compile a list of customers who have received a product based on a potentially defective batch or lot. It enables quick, precise action, blocking any remaining warehoused product from being sold and ensuring consumer safety.

Manufacturer Traceability

Lot control also introduces manufacturing batch-level traceability into your supply chain process. Understanding the performance of specific manufacturing batches is key to efficient product sourcing.

A high defect rate needs to be corrected with manufacturers and facilities, and lot control helps you manage these aspects based on solid metrics. This understanding, fostered by the traceability provided by lot control, allows for more effective negotiations with manufacturers, ensuring better product quality in the long run.

Impact of Lot Control on Inventory Turnover

Enhanced Efficiency and Accuracy

Lot control can boost inventory turnover by streamlining the inventory management process. With lot control, businesses can better plan their production and procurement processes, ensuring that the right products are available at the right time, reducing storage times and faster turnover. This efficiency helps to avoid overstocking and stockouts, which can be detrimental to business operations.

Improved Quality Control

Quality issues can significantly impede inventory turnover. When a problem arises, it’s crucial to quickly identify and isolate the affected items to prevent further issues. With lot control, businesses can trace a problematic product back to its production batch.

By identifying if a specific batch is the source of the problem, they can quickly address the issue, potentially averting a broader recall and accelerating inventory turnover.

Better Demand Forecasting

Lot control provides detailed insights into the movement and performance of different batches of products, enabling businesses to better forecast demand. This understanding can inform procurement strategies, ensuring businesses have the right amount of stock to meet demand, thereby enhancing inventory turnover.

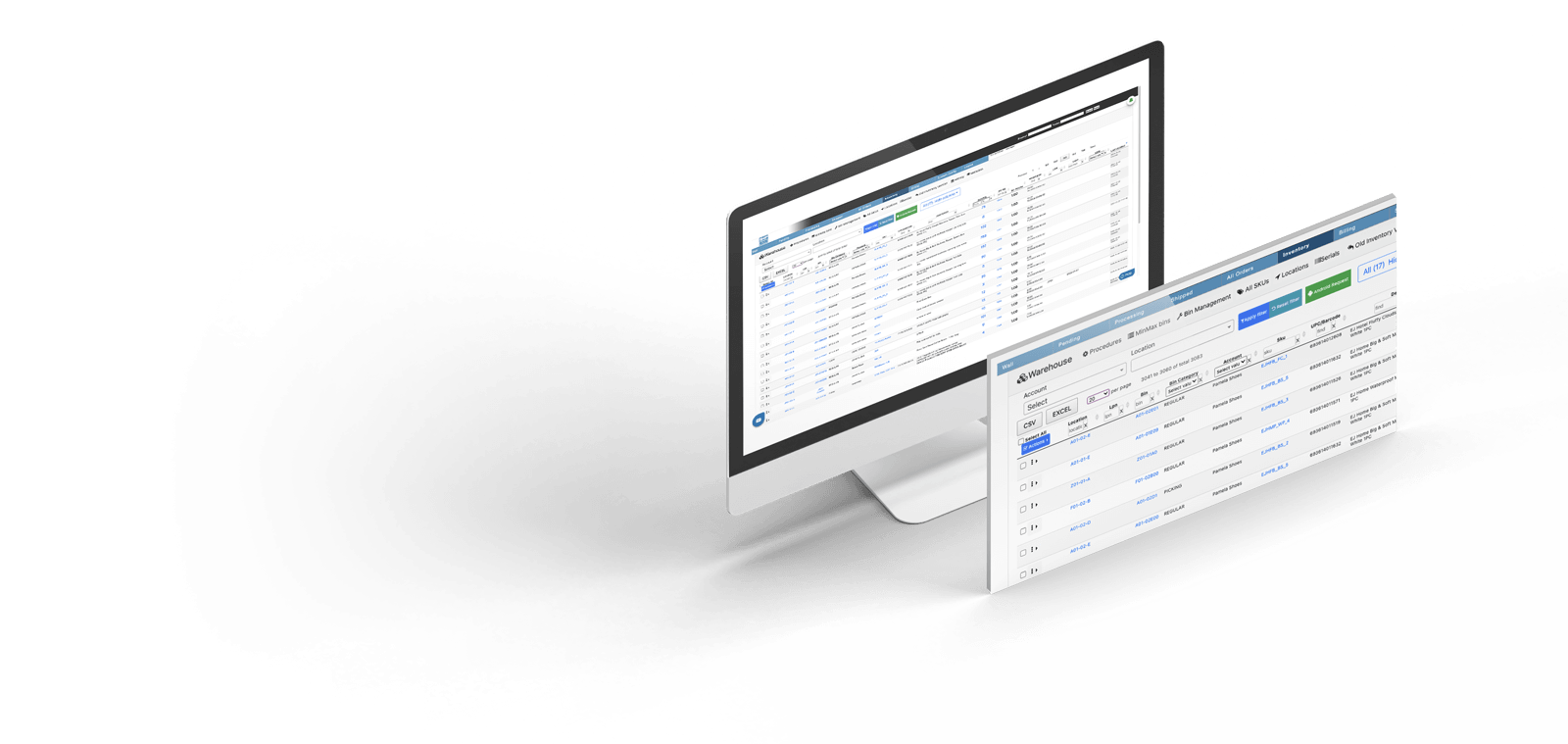

Discover how our WMS can improve your business

Lot Control Best Practices

Maintain Accurate Records

Accurate record-keeping is at the heart of effective lot control. Businesses must ensure that all necessary details, including manufacturing dates, batch numbers, and any relevant quality control information, are accurately recorded and stored. An organized system of record-keeping is vital for traceability and efficient problem resolution.

Incorporate Automation

Manual tracking of lot numbers can be cumbersome and error-prone. When dealing with high volumes, manual processes may not even be a feasible option. Implementing automated systems like Shipedge can greatly simplify the process, improving efficiency and reducing the potential for errors. Automated systems can track lot numbers from the point of production to the end customer, ensuring high levels of traceability.

Regular Audits

Regular audits of your lot control processes are necessary to ensure their effectiveness. Audits can help identify potential issues or areas for improvement, ensuring that your lot control practices are always optimal.

Role of Shipedge in Improving Inventory Turnover with Lot Control

Automated Lot Control

Shipedge’s advanced Warehouse Management System (WMS) automates the lot control process, providing businesses with real-time visibility into their inventory. This visibility, combined with the ability to track products by lot number, enables businesses to quickly respond to issues, improve their procurement strategies, and enhance inventory turnover.

Compliance Support

In many industries, regulatory compliance is a necessity. Shipedge’s lot control features can be a game-changer in maintaining compliance, allowing for easy reporting and demonstrating transparency and adherence to industry standards.

Recall Management

Shipedge’s lot control capabilities also support effective recall management. In the event of a product recall, the system can swiftly identify affected lot numbers and block any remaining warehoused product, ensuring consumer safety and protecting businesses’ reputations.

READ MORE: Your Inventory Lot Control Solution

Case Study: Shipedge’s Impact on Inventory Turnover

- Boosting Efficiency: Shipedge’s lot control system has had demonstrable effects on warehouse efficiency. By automating lot tracking, businesses have reported improvements in inventory accuracy, resulting in less overstocking and stockouts. This efficiency not only reduces holding costs but also ensures products move smoothly through the supply chain, directly influencing inventory turnover rates.

- Ensuring Quality: Shipedge’s lot control capabilities significantly enhance quality assurance processes. The system allows businesses to track product defects back to specific production lots, facilitating quick and targeted responses to quality issues. By swiftly addressing and resolving these issues, companies using Shipedge can reduce their inventory of flawed goods, further accelerating inventory turnover.

Conclusion

To summarize, lot control is invaluable for businesses looking to improve their inventory turnover. It enables them to keep a close eye on their inventory, enhances efficiency, and assures quality by allowing products to be traced back to their specific production batch. Moreover, it equips them with vital insights that can inform better demand forecasting and procurement strategies.

Discover how our WMS can improve your business

Shipedge’s advanced Warehouse Management System, with its automated lot control capabilities, stands out as a practical solution to leverage the benefits of lot control. Whether for enhancing efficiency, supporting compliance, or managing recalls, Shipedge is designed to assist businesses in navigating their inventory management challenges. By implementing such systems, businesses can work towards their goal of improved inventory turnover, contributing to their bottom line and facilitating sustainable growth.

0 Comments