The picking method used in warehouse operations plays a crucial role in determining the speed and accuracy of fulfilling customer orders.

The process of picking involves retrieving items from storage, preparing them for shipment, and choosing the best picking method for an efficient and cost-effective operation. In this blog post, we will explore the different types of picking that warehouses use, including batch picking, cluster picking, and picking to carton, along with some other popular picking types. Later, we will also discuss how each type of picking method can be utilized to maximize efficiency in your warehouse.

1. Batch Picking

Batch Picking is a popular method of retrieving items in the warehouse where orders are grouped together and picked at the same time. This method is often used when there are multiple orders that share a common item, or when items from multiple orders are stored in the same location.

By using this style of picking, laborers can save time by reducing the number of trips to the same location. Additionally, batch picking reduces the amount of time spent on order preparation, as items are already grouped together. Finally, this picking method reduces the risk of errors by allowing the picker to verify all items at once, rather than for each individual order.

Here’s an example of a warehouse that may benefit from batch picking:

A clothing retailer uses batch picking to fulfill orders for a popular t-shirt. Since multiple orders require the same item, the retailer groups these orders and picks them at the same time, reducing the number of trips to the same location and making the picking process more efficient.

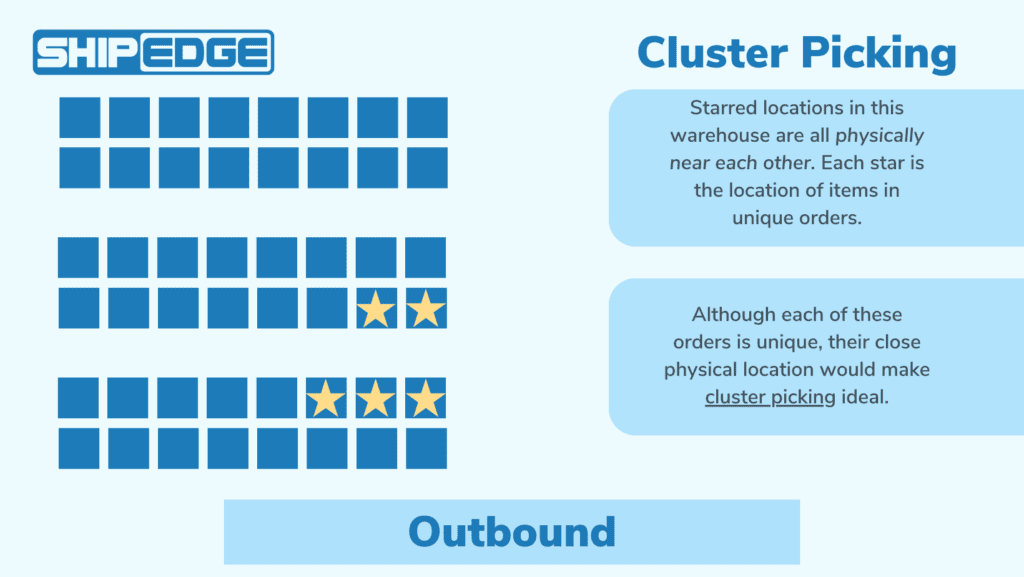

2. Cluster Picking

Cluster picking is a variation of batch picking, involving grouping items together based on their location in the warehouse. This method is used when items are stored in different locations and when there are multiple orders that require items from multiple locations.

Cluster picking is beneficial in several ways, including:

- Time reduction: Pickers only need to visit each location once

- Reduced errors: Pickers only need to verify items once

- Streamlined process: Multiple items for multiple orders can be picked from multiple locations in one trip

An example of a warehouse that may benefit from cluster picking could include:

A warehouse that stores electronic items uses cluster picking to fulfill orders that require items from different locations. By grouping items based on their location, laborers can reduce the amount of time spent traveling within the warehouse, making the picking process more efficient.

3. Picking to Carton

The picking-to-carton method involves picking items directly into a carton or box, making this style ideal for smaller or lightweight items. By allowing the picker to both pick and pack in one step, laborers save time and reduce the risk of errors.

A few examples of when picking to carton would benefit warehouses to improve efficiency include, but are not limited to:

- Beauty brands selling a variety of small-sized items

- Warehouses for small consumer electronics (headphones, phone cases, etc)

- Pharmaceutical warehouses dealing with smaller drugs or medical devices

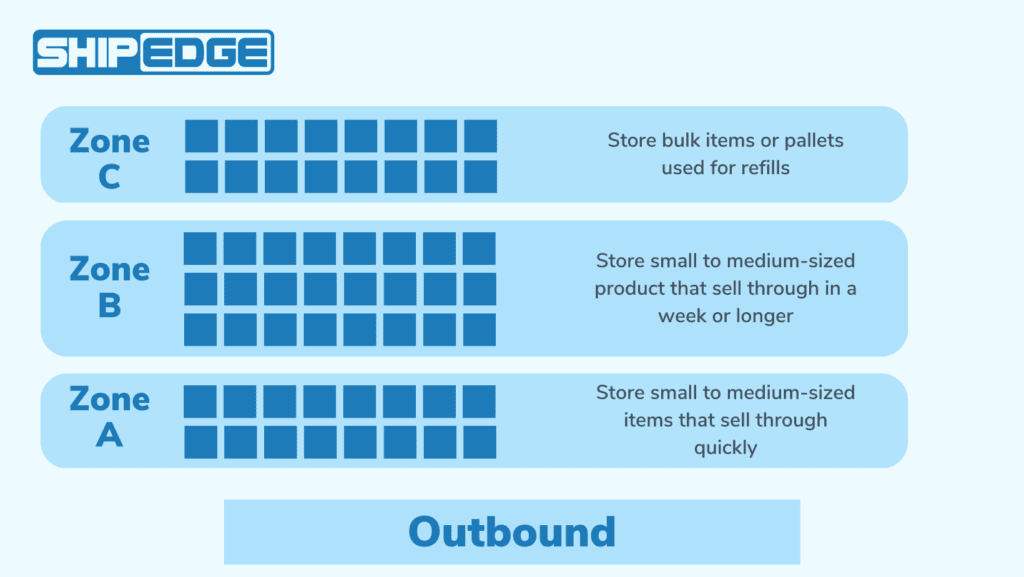

4. Zone Picking

Zone picking divides the warehouse into sections or zones, with items stored and picked according to their designated zones. Each picker is assigned to a specific zone and is responsible for picking items only within that zone. When an order requires items from multiple zones, it is passed from one picker to another until all items are picked.

Zone picking is particularly useful for warehouses with large inventories stored in different locations or those that need to fulfill orders requiring items from multiple locations. By organizing the warehouse into zones, travel time within the warehouse is reduced, making the picking process more efficient.

Use cases:

- Large warehouses with diverse storage requirements

- Food and beverage warehouses with temperature control for perishable items

- Pharmaceutical warehouses that need to separate and store items based on specific conditions

5. Pick and Pass

Pick and pass is a method of picking items in a warehouse where the picker is responsible for picking a specific item, and then the items are passed on to the next person for processing. This method is used when there are multiple items that need to be picked for each order, and when there are multiple steps involved in the picking process. A laborer picks the items and passes them onto the next person for further processing (like packaging or shipping).

Instances that the pick and pass method would be most beneficial in warehouses could include:

- E-commerce warehouses dealing with high-volume orders

- Complex order requirements and product combinations

6. Single Order Picking

In single-order picking, each order requires the individual attention of the picker. Usually, the single-order picking method is reserved for when each order is unique and the items will be packaged and shipped as a single unit

This method of picking is common in warehouses where each order is unique. For instance, custom-made or personalized items in e-commerce orders may only be able to be picked one at a time.

Items that are exceptionally large, bulky, or fragile may also require single-order picking, due to floor workers having to handle these products individually.

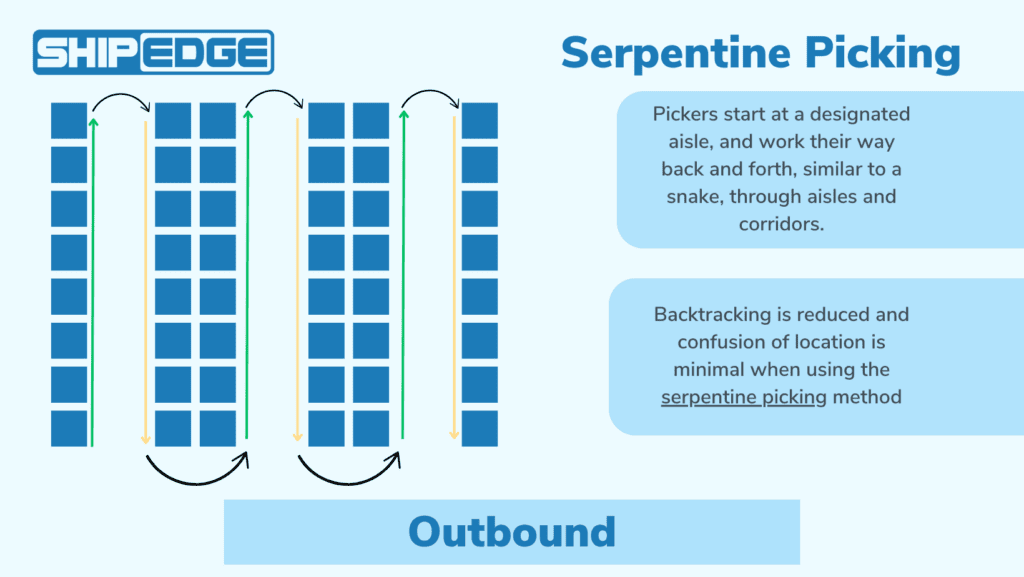

7. Serpentine Picking

Serpentine picking is a picking method when gathering items in a warehouse that involves a continuous, serpentine-like flow throughout warehouse shelves/racks. This method is most frequently used in high-volume operations that require a large number of items to be picked in a short amount of time. In serpentine picking, a laborer will move throughout the warehouse in an up-and-down pattern, picking necessary items as they go. By using serpentine picking, warehouse workers will ultimately spend less time on foot and ensure a picking route that is both efficient and organized.

Serpentine picking is best for warehouses that have a high inventory turnover rate. Some use cases include:

- E-commerce warehouses that experience seasonal or spikes in order volume

- Products or goods that have a quick expiry period

- High-volume warehouses that need to pick many orders at once

Choosing the Right Picking Method

Choosing the right picking method for your warehouse is essential to maximizing efficiency and ensuring that customer orders are fulfilled accurately and on time. By understanding the various picking methods and their respective use cases, you can make informed decisions that will improve your warehouse operations and help your business succeed.

If you’re still unsure which type of picking would most benefit your warehouse, one of our solutions engineers can help you determine the best method for your specific needs.

Discover how our WMS can improve your business

0 Comments