Inventory Lot Control

WMS Feature Highlight

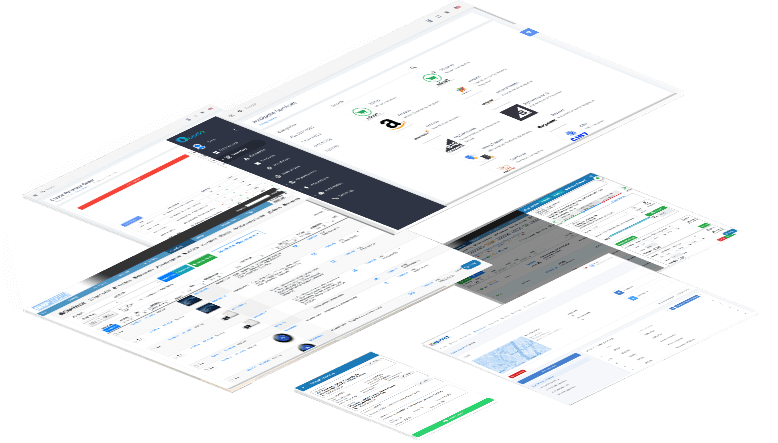

Simplify warehousing operations with our inventory lot control features.

Inventory lot control introduces manufacturing batch level traceability into your supply chain process and protects your customers.

Our warehouse management system automates the inventory lot control process.

Inventory Lot Control

Main Feature Benefits

Compliance – Many industries need to comply to certain rules or regulations and lot tracking can be a tool to ensure compliance.

Protect Customers – In the event of a recall lot tracking allows you to quickly compile a list of customers who have received your product based on a bad batch or lot. This allows for swift action. Any remaining warehoused product can also be automatically blocked.

Sample Industry Use Cases

Manufacturers

Recallable Product Goods

Regulatory Compliance

Many industries require the tracking of lot numbers from the manufacturing process through delivery to customer. Having this information readily available or reporting it to the correct regulatory organization can be automated through Shipedge.

Recall Protection

In the event of a product recall you are able to find out what customers and how many are affected so you can protect your consumers. This also is important to finance, insurance, compliance, and other purposes related to your business operations.

Manufacturer Traceability

Understanding costs and manufacturer or manufacturing plant performance is key to efficient product sourcing. A high defect rate needs to be corrected with manufacturers and facilities. Inventory lot control helps you manage based on metrics.

SKUs / Products & Users allowed

Yearly value of orders shipped

Innovating in commerce systems

Free Consultation

Book time with a solutions engineer to see if our comprehensive commerce platform is a fit.

Common Questions

Inventory lot control is an important part of daily operation so we have tried to make it as easy as possible in our warehouse management system (WMS). Here are some common questions that our users have had when getting started.

What is lot control?

Products are manufactured in batches or tracked by production runs.

Most manufacturers of products use a lot number tied to the production lot it was produced in.

These numbers are useful in inventory lot control or tracking the product and its quality as it makes its way through your supply chain to the end consumer.

How do I use lot numbers in ecommerce?

Lot numbers or batch numbers can be used when customers or your QC team (in a fulfillment facility) catches product defects.

Knowing which lot number the product belongs to enables you to contact your supplier to ask for refunds.

Inventory lot control in a system like Shipedge also lets you trace the product to ensure that there are not bigger issues with the production lot as a whole.

What are lot numbers used for in inventory management?

Manufacturers assign lot numbers to a specific batch or run of a product they produce.

When you are sourcing your products having this data is important for managing the relationship with your suppliers.

If you have product defects at any point you have traceability in an advanced WMS like Shipedge.

This lets you track the product back to a specific production lot, batch, or run and helps you work with your manufacturer to correct production issues or ask for refunds.

Simplifying digital commerce with powerful solutions

Book a Free Consultation with a Solutions Engineer

Check our open calendar after you hit submit to find a time that works for your team.

Every organization is different, so a solutions engineer will work with you to identify your biggest challenges and the best possible solutions to overcome those challenges.