Here we are again at the beginning of a brand new year!

The New Year is a great time to start reevaluating your processes to identify where you are efficient in your workflows, where bottlenecks are occurring, and whether or not you are compliant with safety procedures.

Although the holiday season may be over, returns and exchanges for gifts bought during that time period are just beginning. In this article, we discuss how reverse logistics plays a part in your supply chain, particularly in Q1.

Returns

There are plenty of reasons a customer might return an item or product- many of which are to no fault of the retailer. Products could have been damaged in transit, they may have ordered or received the wrong size, or consumers could have simply changed their minds after purchase.

One aspect of your supply chain that is bound to see an increase in the New Year is your returns and exchanges. Products that were bought as gifts for the holidays are now starting to be returned or exchanged. According to a study, 80% of retailers expect to receive the majority of their returns in January. Another nearly 5% expect most returns to occur in February.

Up to 30% of all products ordered online are returned. This is drastically higher than brick-and-mortar stores, coming in at nearly 9%. Almost a quarter of those online orders are returned because they received the wrong item!

What does this mean for e-commerce business owners and 3PLs managing warehousing for e-commerce-driven companies?

Managing returns effectively is an essential part of running a successful business.

Ensuring that you are managing returns and exchanges as efficiently as possible will prevent the waste of valuable resources, time, and energy. Not only is it important to track returns and exchanges efficiently, but oftentimes, returns are not necessarily a bad thing! A smooth returns or exchange process for the end consumer builds a stronger relationship between the brand and the customer, which may lead to a repeat buyer.

To avoid mistakes and create a valuable brand experience, we recommend using a returns management system in conjunction with your warehouse management system (WMS).

ReturnGO

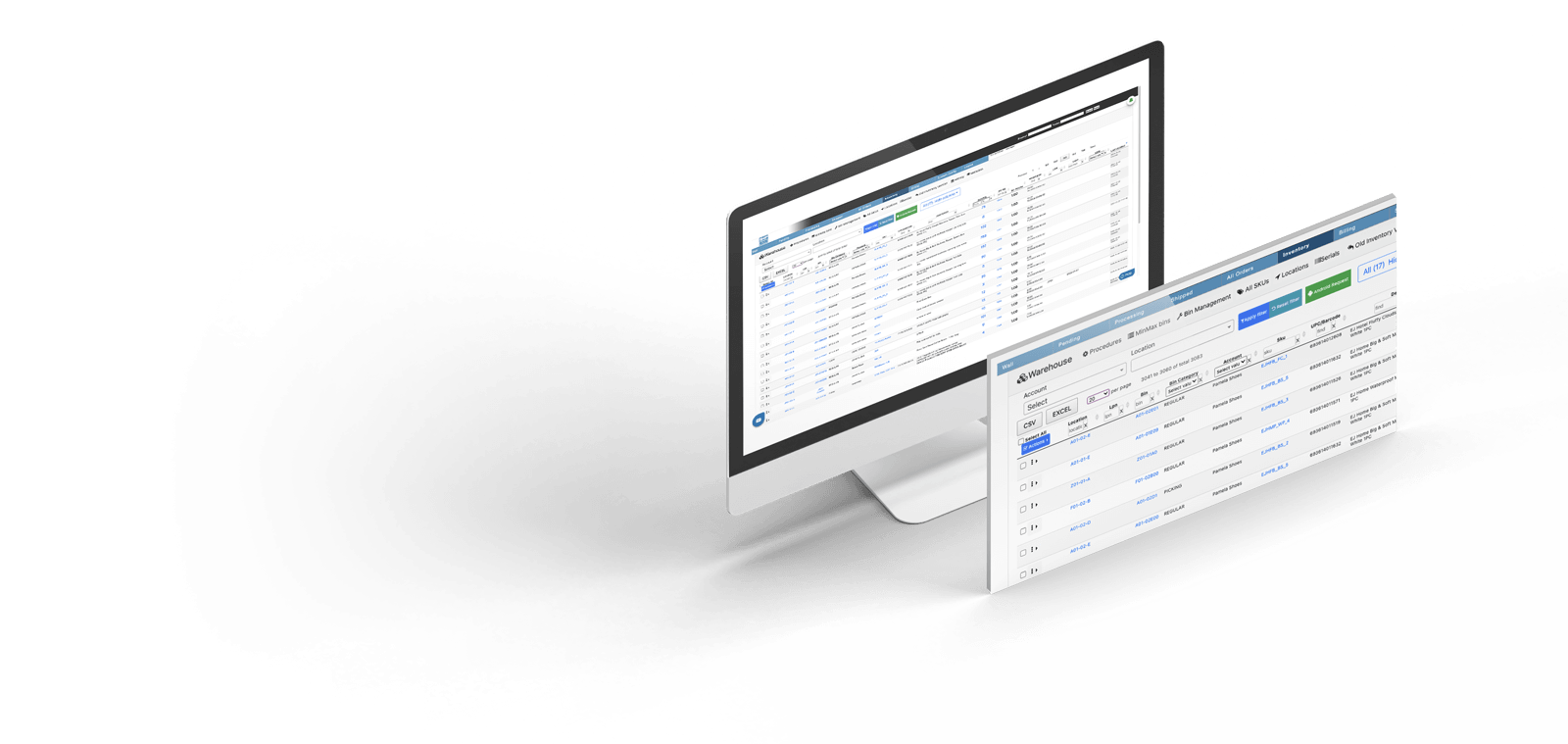

Return management software, like ReturnGO, has the ability to integrate with Shipedge’s WMS. This means that once a customer initiates a return or exchange in your custom-branded portal, ReturnGO’s software will automatically communicate this information to your warehouse and inventory management system.

With the customers’ ability to choose from several different returns options, this turns what would normally be a complicated process full of frantically filled-out spreadsheets and unorganized emails into a hands-free operation. All that’s left for you to do is sit back and watch in real time as returns and exchanges are tracked and managed for you.

Receiving Returns to the Warehouse

This process is similar to your normal receiving routine. The returned product is shipped back to your warehouse, and you can use your WMS jointly with your hand-held scanning device that has the Shipedge app to ensure the product being returned is the product that was originally purchased!

According to the National Retail Federation, in 2020, around 6% of returns were fraudulent, resulting in a $25 billion loss in merchandising returns.

After a laborer receives a return in the warehouse, it is their job to verify that the return is up to the brand’s return standards. This includes checking for damage or defects, and ensuring that the product being returned is what the return merchandise authorization (RMA) says it is.

Exchanges

Sending an exchange is a bit more involved than receiving a return and issuing a refund or store credit for the product.

As returns come into the warehouse, laborers should verify that products are what they say they are, and what the quality is.

Based on inventory availability reported in your WMS, your customer is able to make an exchange in their ReturnGO portal.

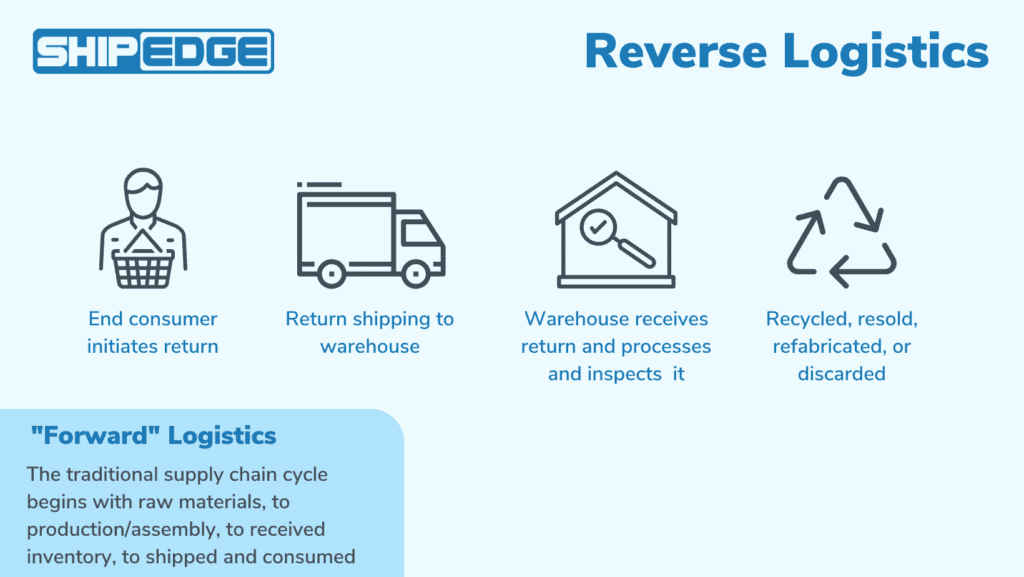

Reverse Logistics

Warehouses should have a plan in order on what to do with returns and/or exchanges being shipped back to them. The process of getting the product back from the end consumer and finding a place for it in the warehouse (or somewhere else) is called reverse logistics. The product is moving backward from the traditional supply chain format.

There are many considerations to make before the product is even sent out to the customer, in the event that they do return the product. This may include, but is not limited to:

- How many days do they have to return the product?

- Is there a special holiday return policy?

- Can the product be returned to a physical store?

- What is the cost of shipping the product back to you? Is this something the company will pay for or is it the responsibility of the customer?

- Can the product be resold, recycled, or disassembled and reused in another way?

- If not, would you consider letting the customer keep the product and issuing a refund?

Handling a return, exchange, and managing reverse logistics can be both simple and fruitful for your company, given that you give yourself the right tools. You can cut down a tree with an axe, but it’s much easier with a chainsaw. The same is true for your software stack- make things easy on yourself!

0 Comments